Baby Shay:

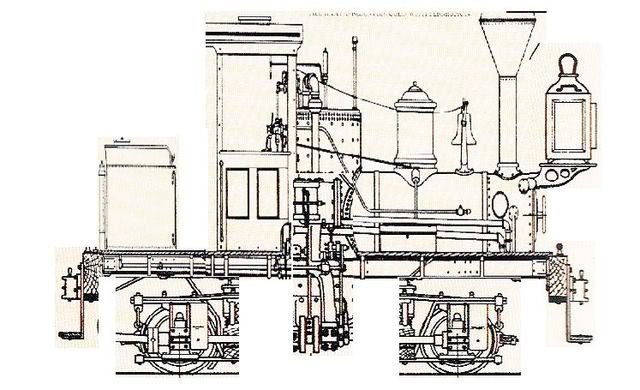

Several months ago I spent some time looking at articles in back issues of the Narrow Gauge and Short Line Gazette about the T-Boiler Shay engines. I wondered at the time why they never made a one cylinder version.

I asked at my local train store if their was a prototype for a one cylinder Shay? The answer was that they didn't think there was. Their collect thought was that a one cylinder version might work but it would not be very effective. Two or three cylinder versions, however, were very effective.

Time passed and last week I was looking at the October 2008 issue of Garden Railways magazine. I look at most of the train model magazines each month and buy a few if they have an article of interest to me.

To my surprise I found my one cylinder Shay prototype. A modeler named Jerry Barnes had built a "G" scale one cylinder Shay for his "Spring Creek Railroad". I did a internet search for the "Spring Creek Railroad" and found a very nice web site. Jerry has a really nice "How-To" for his one cylinder Shay.

http://thescrr.com/shay.html

I discovered also that Jerry had built several "G" scale McKeen's. He has a brief "How-To" article in the August 1997 issue of the Garden Railroad magazine. I had bought that issue a year or so ago when I was gathering my McKeen reference material. Small world.

The McKeens are about 6 down on this page:

http://thescrr.com/rollingstock.html

I was able to talk to Jerry on the phone and he sent me a few more photos of his one cylinder Shay.

Now that I have a prototype for a one cylinder Shay I went to work.

My "Baby" Shay would be built first in HO scale, one or more, and then maybe also in HOn3.

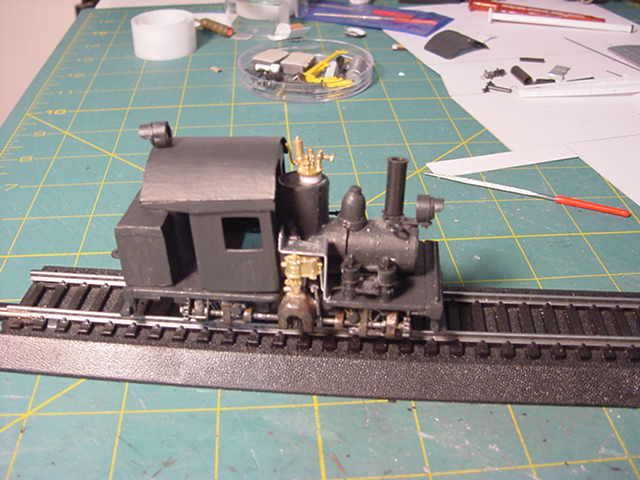

The "Baby Shay" will be a combination "Kit-Bash" of a few parts from both MDC and Keystone Shay kits and a big dose of scratch built parts.

To figure out how to make a one cylinder steam thing I first built a two cylinder that came in a Keystone Shay kit I have. I then took another two cylinder motor and modified it to a one cylinder. Keystone sold these two cylinder kits and Caboose Hobbies or Walthers may still have some. I bought 5 or 6 from Caboose Hobbies on sale. I bought all they had. I made 3 different one cylinder Keystone versions. They didn't stayed glued together very well.

I didn't really like the Keystone versions. I got out all my pictures of two cylinder Shays and found one I liked. I made a cardboard version to get the size correct. I started one in Styrene this afternoon. I think I spent 40 or so hours on the Keystone versions so I hope the Styrene version goes faster.

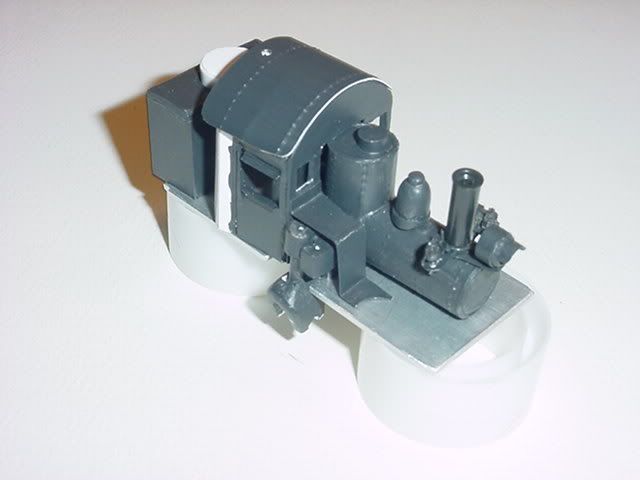

2)

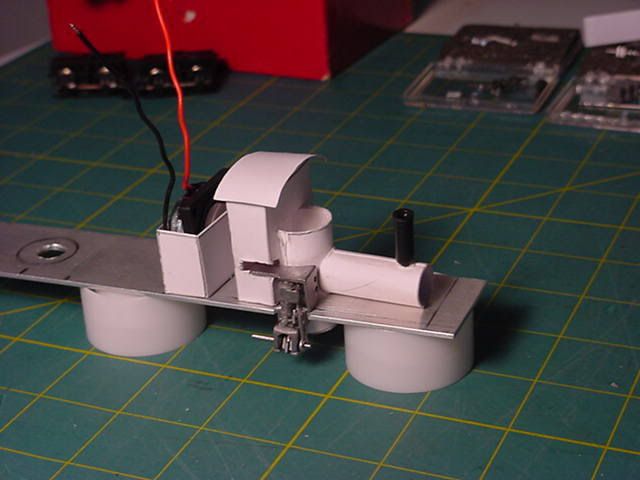

This it will be a working model. Not like Jerry's as his is a lot bigger. The "working" part is taking a bit of imagination as this Shay is very small.

It will have a Micro-Tsunami DCC with Shay sound, a NWSL motor, one of the new 1" square Bass Reflex Speakers from Railmaster Hobbies and LED's for lights .

http://www.railmasterhobbies.com/Speakers.htm

You can see the speaker in one of my pictures. The RailMaster speaker comes ready to use with a built in enclosure. They also sound great. The speaker will be built into the small oil tank on the rear of the Shay. I am also building a small tender like piece of rolling stock for extra water and more oil to go with the "Baby Shay".

I have the power unit and speaker and the Micro-Tsunami decoder is on order at my local train store.

I hope to be working on the Shay drive system this weekend.

3)

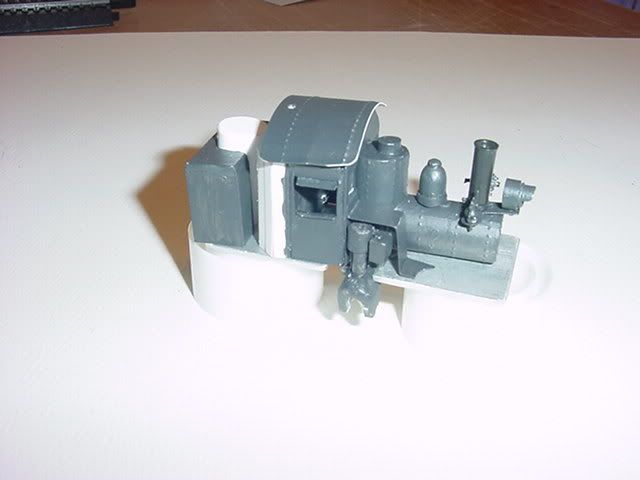

I am slowly making a bit of progress on the Baby Shay. I need a bunch of detail parts and will call an order in this afternoon to Precision Scale Co (PSC). They have all the parts I need but they are really slow to get an order together and ship. I know it could will be several weeks before I see my order. I got a bunch of PSC parts from Caboose Hobbies this week but they didn't have everything I wanted.

1. Work Bench.

2. Making T-Boiler.

3. Making slow progress. If you look close you can see the top of the small speaker standing up in the cab.

4)

I added up the cost for the parts I wanted and it came to about $200. I started looking for a way to make some of the detail parts and have looked at my junk stuff to see what I can use. I could buy 2 Backmann 3 truck Shays (less DCC) for a bit less than all the parts were going to cost.

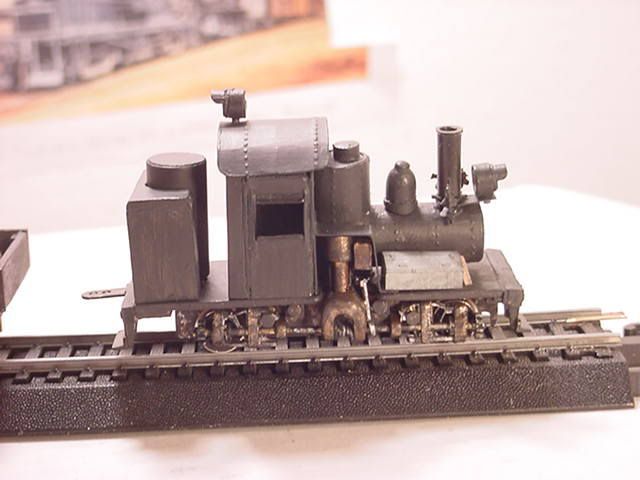

This picture was with a flash. That was the only way I could get the bell, headlight, generator and the bracket that those things sit on to show up enough to see them. The headlight will be wired for an LED. I am not sure a generator would or could be put on that bracket by the smoke stack. I have to check on that.

5)

Here are a few better pictures of the top part of my Baby Shay.

1.

2.

3.

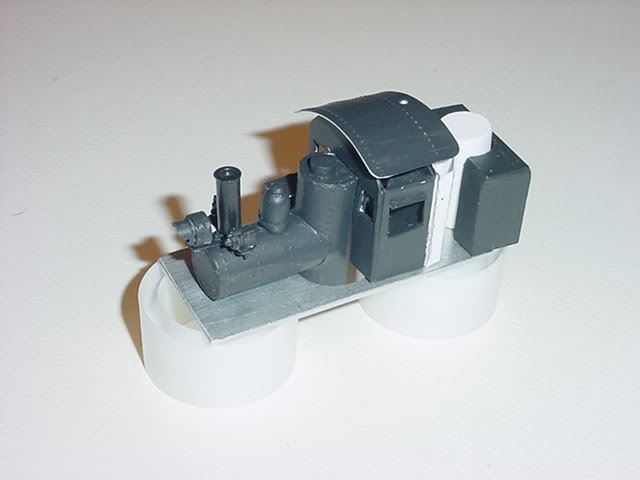

I have been working on making the geared side of the Shay. It took me so many hours to get it made and rolling smooth. I almost went crazy. Had to push back and go for a walk to think about what I was going to try next. I about started over and built in a lot of different ways to adjust the line shaft, geared wheels, gears on the line shaft and two new supports for the line shaft. I made most of the connectors by taping holes (making threads) and using screws with lock nuts.

4.

I will start on the side frames for the other side this week. This is the side where the wheels just roll so all I need to make are the side frames.

6)

I have been trying to get my Baby Shay ready for its Tsunami Micro Decoder w/sound. I have the decoder and with a little luck it should be in and running by the end of the week.

I have been trying to finish up the under part of the chassis and adding a few details. I still have a bunch of detail parts to add and some weathering.

My little speaker is missing and I suspect one of my cats has taken it and made a cat toy out of it. I am still looking for it with no luck so far.

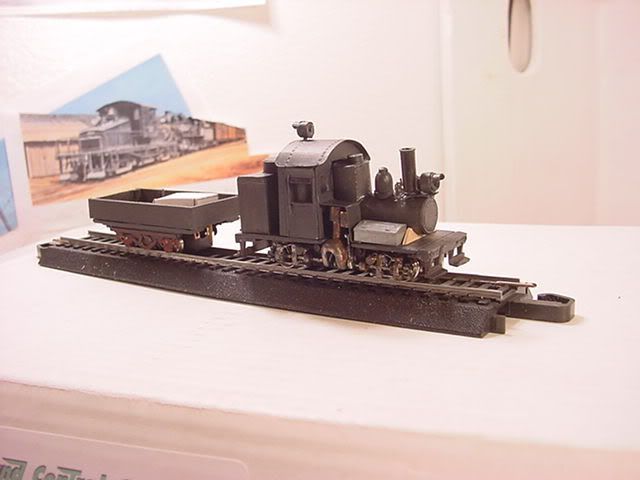

1.

2.

3.

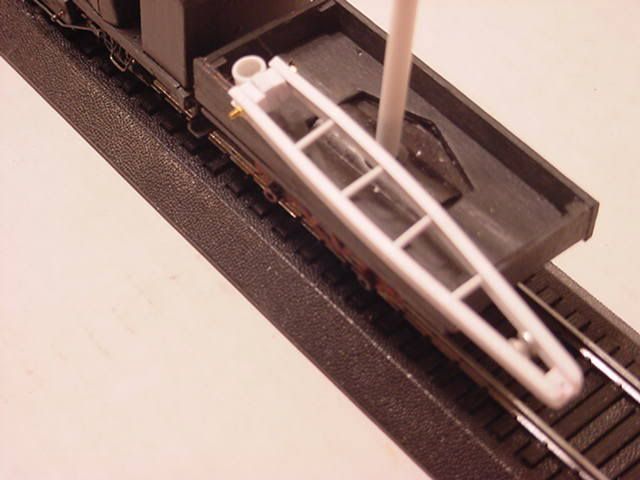

4. The little white box in the trailing car is the same size as the Tsunami Decoder. The Tsunami Micro Decoder is the HO version.

7.

This is the most ambitious train project for me to date. Watching others build stuff gave me the courage to try this. I have learned a lot and see a few things now that might have made it a bit easier. I will try those ideas on the next one.

I am not finished yet but I can see the light at the end of the tunnel.

I am thinking about a couple of changes, one would extend the cab roof back to the forward edge of the oil and water storage tanks. That might get rid of the "outhouse" look that I see in the cab at this time. It also seems that a bit more roof area would give the crew some weather protection that they don't have now. The roof will be a 5 minute fix if it works and if I don't like it, it is after all just a small piece of card stock.

The trailing car will be some type of service car for the McKeen's. I am not sure yet just what it will look like as a finished car. I am looking for pictures or ideas for some kind of funky service car if anyone has something to offer. I think some type of small crane to lift or tow with, gas tank for refueling, and maybe some type of fire fighting equipment. The sides on the follow along car come off and may not even be used. It can become a small flat car easy.

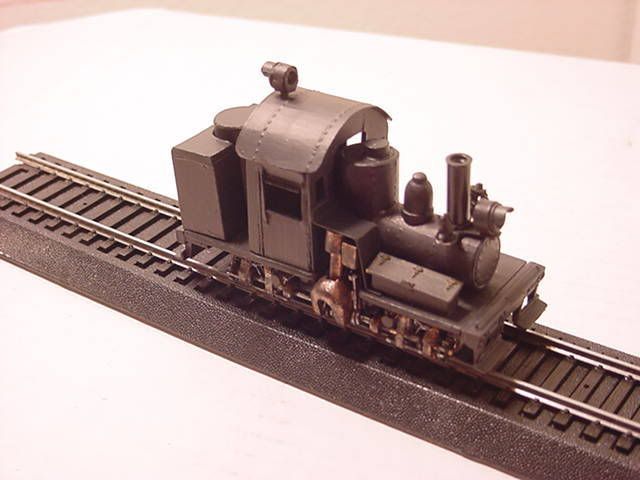

8)

I spent the last few days working on the part that no one will see. The under side of the chassis that holds it all together. That part is done and I can now pick the Shay up without the wheels falling off. I started work on the non-gear side frames and have finished them. I added a few other wire details such as the steps up into the cab, the ash removal thing and a wire brace, and a wire something on the front bumper thing. Someday I may figure out the names of these parts. I made all these parts from thin wire that came in one of my MDC Shay Kits. I still have a little more detailing to finish and at least one change to something I am not completely happy with.

1.

2.

One of the things that I want in the follow along car is a crane. I needed a few really small pulleys and didn't have any. I came up with an idea for pulleys that I think is going to work just fine. These picture are more to show the pulley on the end of the crane. The pulley is 5/32" and will turn but I don't think it needs to for this car.

I am thinking about writing up a short "How To" for the way I made the pulleys. I think Warren and I talked about looking for small pulleys one night in Chat. If someone else has any ideas for making your own pulleys I would be interested in seeing how you did it. I can make the pulleys in 7 different sizes. The smallest is 3/32" up to 9/32".

3.

4.

====

Pulleys How-To:

I have been looking for really small pulleys to use with HO scale things for awhile. I have had this "Hand Punch" set from Harbor Freight Tools for several years and used it a lot on backpacking gear I make for myself. The punch works really great and the metal punched out made me think of the side pieces of a pulley.

Item number 44060 http://www.harborfreight.com

A couple nights ago I thought I would try to use the punched out pieces and make a couple of pulleys.

The punch set comes with 7 different hole sizes.

For this demonstration I am using the largest size - 9/32".

I have punched a number of different types of metal. For the pulley I used some 1/32" aluminum. You need a hole in the small punched out piece and I found out it is much easier to pre-drill the metal. To make it a bit easier I drilled a hole in the aluminum and then used the hole as a punch guide. The plastic rod I used for the pulley is 3/32" from Plastruct, item #90856.

1.

2.

3.

4.

5.

6.

7. Example. Put the two pieces on a plastic or some type of rod, add a drop of glue to hold the disks to the rod. Trim rod to fit your needs. You could also add something as a spacer and make a take-up reel such as you might find on a crane

I expect that there are many other uses for these punched out pieces.

====

9)

I needed an air tank and the ones I had were either to big or to small. I decide to get the "punch" out again and see what I could come up with. I had a cat medicine dispenser about the right diameter for the tank size and punched 2 holes in my thin aluminum for the tank stands. I then filed the extra material away till they were nice and thin. Next I punched two holes in some thin sheet styrene for the tank ends. I did a bit more filing and glued all the parts together. Almost, instant air tanks.

1.

2.

3.

4.

==

Current pictures of my Baby Shay. You may notice a few changes. I came up with what I think is a better looking power cylinder. I also will run some plumbing from and to some of the detail parts before it is done. I have one more day to work on the details till it goes into the shop for some electrinical work. I am not gluing the details on until all the shop work is finished.

5.

6.

10)